MTI Partners With Hero 2 Hired To Help Create Jobs For Veterans

January 14, 2016MTI Leads Additive Manufacturing Companies With C-103 Metal 3D Printing Milestone

March 2, 2016Why MTI Laboratory Crucibles Last Longer

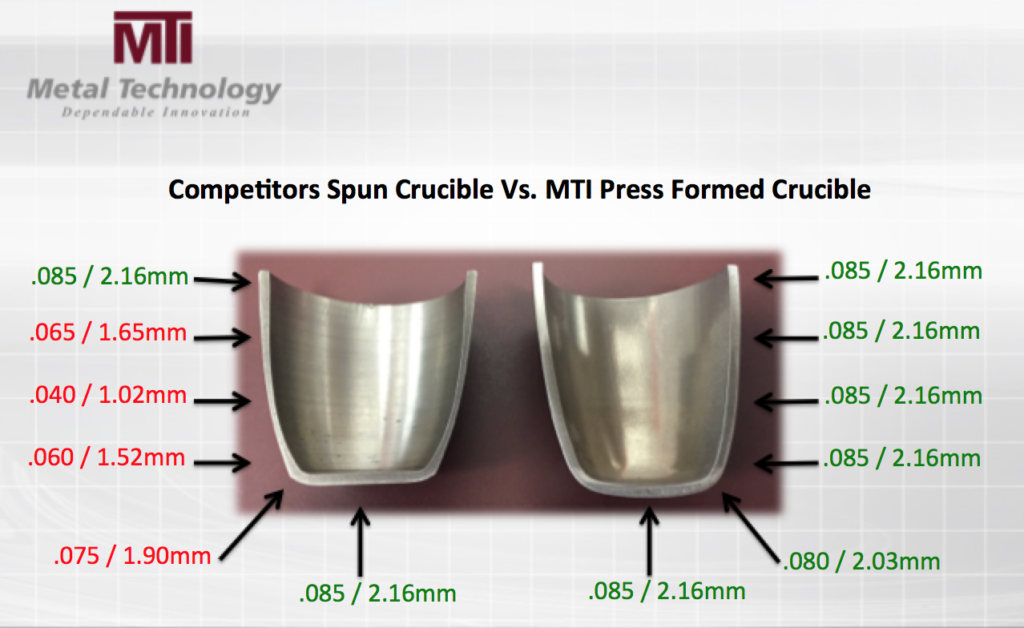

MTI has been manufacturing laboratory crucibles out of Zirconium, Molybdenum, Niobium, Tantalum, Titanium, Vanadium, Nickel, and Inconel for over forty years. We are often asked by our customers why our crucibles last longer than other suppliers and the answer to that question comes from how our crucibles are made. We made the decision many years ago to press form our crucibles instead of spinning them because we believe that press formed crucibles provide much better overall quality for the following reasons.

- Press formed crucibles will typically have a more consistent wall thickness throughout the crucible.

- Press formed crucibles will be more consistent dimensionally when compared to typical hand spun crucibles.

- Some hand spun crucibles we have seen have shown localized wall thinning of approximately 50%, meaning that you are really buying a 1mm wall thickness crucible and paying for a 2mm wall thickness crucible.

- Most hand spun zirconium crucibles are heated while spinning and thus form oxides on the surface, affecting grain size, which could affect the life cycle of the crucible. MTI cold forms their crucibles to assure that the material properties are not impacted.

Below is a comparison of an MTI press formed 2mm zirconium crucible compared to a competitors 2mm spun crucible, note the variation in wall thickness on the spun crucible.

About Metal Technology (MTI)

With more than forty years of experience applying innovative, proprietary technologies, Metal Technology (MTI) is making possible the use of difficult alloys for a wider range of applications with greater efficiency, versatility, and reliability. Alloys include Tantalum, Niobium, Zirconium, Titanium, Tungsten and Molybdenum. MTI uses specialized deep-draw, spinning, forging, machining, EDM, and additive manufacturing methods to deliver superior products according to your exacting specifications.

Contact us for more information on our full line of laboratory crucibles.