MTI Advances Initiative To Lead 3D Metal Printing Companies In The Use Of C-103

Metal Technology (MTI) has entered the next stage of development required to complete company initiatives focused on leading 3D metal printing companies in using C-103.  These efforts have been concentrated on developing 3D printing components using C-103, a Niobium based alloy containing approximately 10% Hafnium and 1% Titanium. MTI has successfully spheridized a sample batch of the C-103 powder that is widely used in space applications because of its excellent formability, cost, weight, and reliability.

These efforts have been concentrated on developing 3D printing components using C-103, a Niobium based alloy containing approximately 10% Hafnium and 1% Titanium. MTI has successfully spheridized a sample batch of the C-103 powder that is widely used in space applications because of its excellent formability, cost, weight, and reliability.

Jason Stitzel, Director of Engineering for MTI, had good things to report regarding the work with C-103:

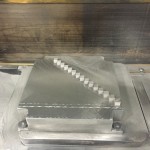

“We loaded a small batch of powder that has gone through spheridization into

our direct metal printing equipment and ran two sample burns. Initial results are very promising. Powder flow is much better than unprocessed powder and layering is much smoother.”

Far Ahead Of Other 3D Metal Printing Companies

MTI was the first to create C-103 powder for use in powder-bed laser as well as other additive manufacturing equipment. We are now testing a refined spheridized version of the powder.

This next round of testing will help as MTI advances further down the road to developing complex components for Space Primes such as Aerojet Rocketdyne, ATK, Boeing,  Honeywell, Lockheed Martin, Moog, NASA, Orbital Sciences, Pratt & Whitney, Sierra Nevada Corp., SpaceX, United Launch Alliance, UTC Aerospace and others

Honeywell, Lockheed Martin, Moog, NASA, Orbital Sciences, Pratt & Whitney, Sierra Nevada Corp., SpaceX, United Launch Alliance, UTC Aerospace and others

About Metal Technology (MTI)

With more than forty years of experience applying innovative, proprietary technologies, Metal Technology (MTI) is making possible the use of difficult alloys for a wider range of applications with greater efficiency, versatility, and reliability. Alloys include Tantalum, Niobium, Zirconium, Titanium, Tungsten and Molybdenum. MTI uses specialized deep-draw, spinning, forging, machining, EDM, and additive manufacturing methods to deliver superior products according to your exacting specifications.

Contact us for more information on our additive manufacturing initiatives.