MTI Partners with SEDS of UCSD | Aerospace Additive Manufacturing

April 4, 2016Turbo Collector Project | Stainless Steel 3D Printing

April 29, 2016Need A 3D Metal Printing Service? Answer These 4 Essential Questions Before Requesting A Quote

Here at Metal Technology, we 3D print metal using cutting-edge technology and a fully comprehensive prescriptive approach backed by over forty years of metalworking experience that surpasses any 3D metal printing service available on the market. When it comes to 3D printing – specifically, 3D metal printing – it’s important to ask four questions of yourself before requesting a quote.

Question 1: Is this part suitable for additive manufacturing?

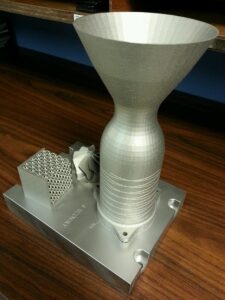

Direct Metal Sintering (DMS) is an additive manufacturing technology with the ability to produce truly unique parts with previously impossible to manufacture geometry in a matter of hours. This technology uses a variety a metals and alloy materials to create strong and durable parts from your 3D CAD (Computer Aided Design) data without the need for tooling or long lead times for materials.

This technology is ideal for the production of prototypes and components with fine detail for aerospace, scientific, defense, motor sports and medical applications.

Does the part you want to print have geometry that can be altered to reduce complexity or cost? Is 3D printing the best solution for your application? In almost all cases we are able to improve the end result by collaborating with our customers during design to help reduce cost, complexity, and help them select the best manufacturing solution to fit their needs.

Question 2: What kind of design definition do I have?

Do you have drawings or models that show exactly what you’re wanting to produce using a 3D metal printing service? This is an important piece of the puzzle that helps provide clarity for both parties.

Question 3: What is the desired quantity?

Here we must differentiate between R&D and Production. Is your product something that will need to be produced in a low volume or high volume? If this decision has yet to be made, let us know and we can help.

Question 4: What is my timeline?

Nailing down a timeline before requesting a quote is essential. Do you need this completed in a week? A month? Next year? Your timeline will dictate the flow of your project and relationship with MTI.

To learn more about the rules of additive manufacturing, check out this interview with MTI’s Director of Engineering, Jason Stitzel:

Receiving A 3D Metal Printing Service From MTI

Metal Technology is committed to employing a highly skilled production team that translates ideas into solutions, for even the most challenging operating conditions. We understand the iterative process required to develop and deploy very complex products and would love to work  with you and your team to create optimum results throughout the project and ensure that we are meeting your expectations at all levels. We are proud of what we do and want to bring your vision to reality! For a good look at all the potential that lies within working with us, check out our Capabilities Brochure here.

with you and your team to create optimum results throughout the project and ensure that we are meeting your expectations at all levels. We are proud of what we do and want to bring your vision to reality! For a good look at all the potential that lies within working with us, check out our Capabilities Brochure here.

About Metal Technology (MTI)

With more than forty years of experience applying innovative, proprietary technologies, Metal Technology (MTI) is making possible the use of difficult alloys for a wider range of applications with greater efficiency, versatility, and reliability. Alloys include Tantalum, Niobium, Zirconium, Titanium, Tungsten and Molybdenum. MTI uses specialized deep-draw, spinning, forging, machining, EDM, and additive manufacturing methods to deliver superior products according to your exacting specifications.

Contact us for more information on our additive manufacturing initiatives.

Or if you are ready to request a quote, please fill out our online form here: