MTI Achieves A “First” Among Additive Manufacturing Companies

July 28, 2014MTI & nuFaktory LLC Join Forces To Lead 3D Metal Printing Companies

September 27, 2014MTI To Exhibit At Applied Superconductivity Conference

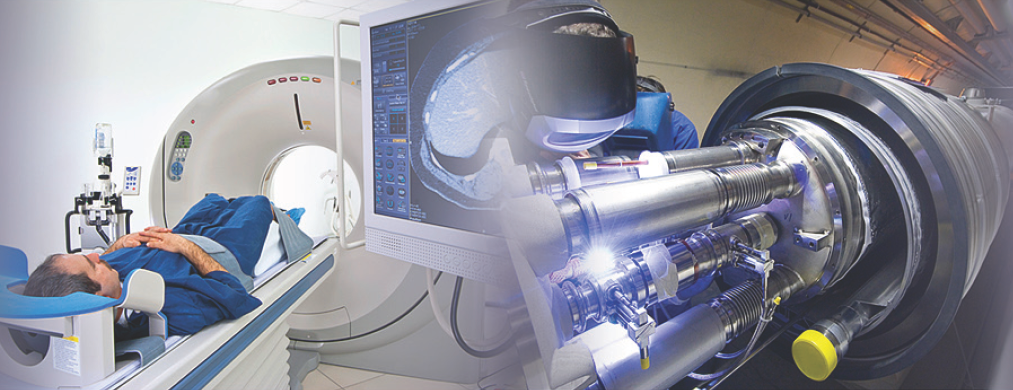

Metal Technology (MTI), an ITAR Certified and ISO9001:2008 Registered company has a long history in propulsion and space applications and is on the leading edge of manufacturing technology in reactive and refractory metals. MTI fabricates components that are used in the superconducting activities around the world including niobium components for Magnetic Resonance Imaging (MRI) machines which when coupled with giant magnets, create the proper level of energy charge to excite soft-tissue structures within the body, revealing denser-tissues.

Additionally, superconducting technology is not only found in MRI machines but is also widely known in the particle accelerator scientific community. Particle accelerators and colliders are best known for their use in particle physics where charged particles are separated at high speeds. Large colliders like the Large Hadron Collider (LHC) at CERN (European Organization for Nuclear Research) and RHIC (Relativistic Heavy Ion Collider) at the Brookhaven National Laboratory are studying and developing many applications for uses in medicine and energy. Globally, with more than 30,000 accelerators in operation, superconductivity science hopes to help solve reliance on fossil fuels. Join MTI at booth #31 to discuss Superconductivity projects and how MTI can help further exploration and development in this vital area of science.

About Metal Technology (MTI)

With more than forty years of experience applying innovative, proprietary technologies, Metal Technology (MTI) is making possible the use of difficult alloys for a wider range of applications with greater efficiency, versatility, and reliability. Alloys include Tantalum, Niobium, Zirconium, Titanium, Tungsten and Molybdenum. MTI uses specialized deep-draw, spinning, forging, machining, EDM, and fabrication methods to deliver superior products according to your exacting specifications. MTI produces components for ion source components, targets, seamless crucibles, explosively formed penetrators, tubing and vessels to custom parts that go beyond common configurations.

Contact us for more information on our additive manufacturing capabilities.