Mechanical Characteristics For MTI 3D Printed Inconel 718 Components

December 10, 2015MTI Takes Delivery Of Mitsubishi BA24 Large Capacity EDM

January 12, 2016MTI Installs New Zeiss Contura To Enhance 3D Metal Printing Service

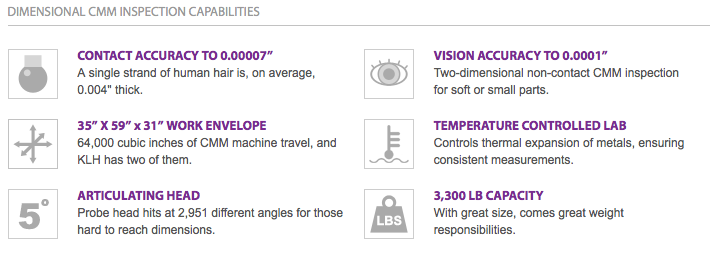

Metal Technology (MTI) recently added a new Zeiss Contura CMM (Coordinate Measuring Machine). This CMM allows for greater precision in our additive manufacturing, 3D metal printing service as well as our other manufacturing services. A CMM is a highly accurate method to measure features on parts in 3-dimensions. This equipment is both manual and highly automatic (depending on the application and requirements). The technology utilizes glass scales along with a multi-head stylus that can easily measure parts within +/- 0.00007″ (a single strand of human hair is, on average, 0.004″ thick).

Check out this video of our new Zeiss Contura CMM in action:

Excellence In Every Aspect Of A 3D Metal Printing Service

Here at MTI, we strive for excellence in every aspect of our work, especially when it comes to a 3D metal printing service. With more than forty years of experience applying innovative, proprietary technologies, Metal Technology (MTI) is making possible the use of difficult alloys for a wider range of applications with greater efficiency, versatility, and reliability. Alloys include Tantalum, Niobium, Zirconium, Titanium, Tungsten and Molybdenum. MTI uses specialized deep-draw, spinning, forging, machining, EDM, and additive manufacturing methods to deliver superior products according to your exacting specifications.

Contact us for more information on our additive manufacturing initiatives.