Turbo Collector Project | Stainless Steel 3D Printing

April 29, 2016CubeSat Engine Successfully Printed | Aerospace Additive Manufacturing

June 24, 2016Full Scale Rapid Prototyping Services From MTI

At Metal Technology (MTI), additive manufacturing (also known as 3D metal printing, or direct metal sintering) is one of our specialties. One of the perks of additive manufacturing is it gives us the capability to provide our customers with full scale rapid prototyping services. It allows us to provide cost-effective, timely, testable prototypes shortly after a design has been finalized.

One example of a success story that has come as a result of our rapid prototyping services is a project that we worked on with Extreme Turbo Systems, a company out of Vancouver, WA. that builds hand-fabricated  turbo applications for high performance vehicles. For Extreme Turbo Systems, the initial path to creating a testable prototype was quite extensive – the hand fabricated piece would have to be digitized, modeled in a CAD program, 3D printed into a plastic model, then tooling would be built, and finally the prototype would be casted for testing. By joining forces with MTI, our rapid prototyping service was able to cut out several phases of the process. Now, Extreme Turbo Systems is able to go straight from a CAD modeled piece to a testable prototype – saving time, money, and resources.

turbo applications for high performance vehicles. For Extreme Turbo Systems, the initial path to creating a testable prototype was quite extensive – the hand fabricated piece would have to be digitized, modeled in a CAD program, 3D printed into a plastic model, then tooling would be built, and finally the prototype would be casted for testing. By joining forces with MTI, our rapid prototyping service was able to cut out several phases of the process. Now, Extreme Turbo Systems is able to go straight from a CAD modeled piece to a testable prototype – saving time, money, and resources.

To learn more about this project, check out our interview with JR Perrott, owner at Extreme Turbo Systems:

Curious about the Extreme Turbo Systems project? Read the full article here.

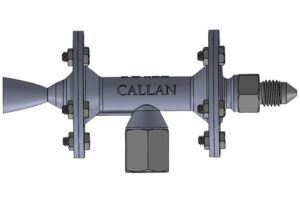

Metal Technology has also had the great privilege of partnering with the Students for the Exploration and Development of Space (SEDS) at UC San Diego in the production of Triteia, a semiautonomous, chemically propelled 6U CubeSat competing in In working with SEDS, MTI has provided rapid prototyping services in the creation of Triteia’s engine, Callan – which has been 3D printed using Inconel 718. Through partnering with MTI, SEDS was able to submit design specifications for Callan and have a testable prototype available shortly thereafter.

and Development of Space (SEDS) at UC San Diego in the production of Triteia, a semiautonomous, chemically propelled 6U CubeSat competing in In working with SEDS, MTI has provided rapid prototyping services in the creation of Triteia’s engine, Callan – which has been 3D printed using Inconel 718. Through partnering with MTI, SEDS was able to submit design specifications for Callan and have a testable prototype available shortly thereafter.

Hear more about this project’s success from SEDS Officers, Darren Charrier and Rohit Ghosh:

To learn more about MTI’s partnership with SEDS, check out the full press release here.

About Metal Technology (MTI)

With more than forty years of experience applying innovative, proprietary technologies, Metal Technology (MTI) is making possible the use of difficult alloys for a wider range of applications with greater efficiency, versatility, and reliability. Alloys include Tantalum, Niobium, Zirconium, Titanium, Tungsten and Molybdenum. MTI uses specialized deep-draw, spinning, forging, machining, EDM, and additive manufacturing methods to deliver superior products according to your exacting specifications.

Contact us for more information on our rapid prototyping services.